Certified wall solution for bathrooms, laundry rooms, and humid environments

At Andronor, we install these systems using TEK17-approved methods and components that follow Norwegian SINTEF recommendations for wetroom performance. Each layer is carefully selected and applied to ensure long-term durability, safety, and hygiene – avoiding issues like rot, mold, or moisture migration.

Where to Use Wetroom Gips Wall Systems – Bathrooms, Laundry Rooms, and More

Wet areas require more than just water-resistant paint – they need an integrated wall system designed to resist moisture penetration, mold growth, and condensation-related damage. This system is ideal for both full renovations and new constructions, where regulatory compliance is a must.

Best For:

- Shower and bathtub walls

- Laundry rooms and technical utility zones

- Bathrooms in apartments, cabins, or hotels

- Commercial washrooms or locker rooms

- Kitchen splash zones or damp basement areas

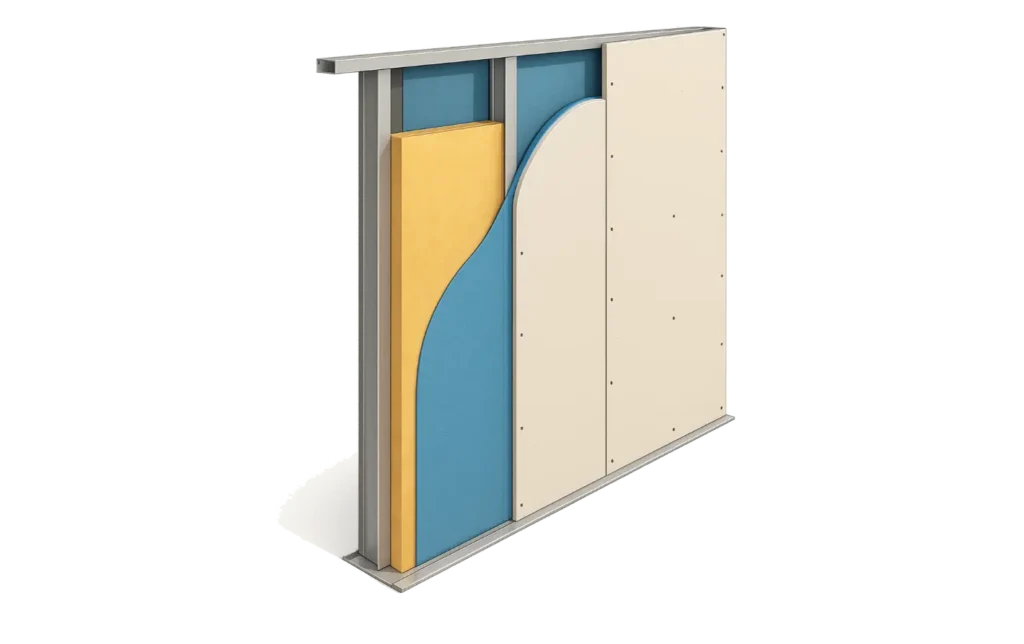

Wetroom Wall System Components – Framing, Membranes & Moisture-Resistant Boards

| Component | Description or Option Range |

| Substructure / Framework | Moisture-treated timber or galvanized steel CW/UW profiles (50–100 mm) |

| Surface Layer | Mold-resistant gips boards (e.g., Gyproc Glasroc H, Norgips Humidboard, Knauf Green Gips) |

| Barrier Membrane | Vapor-tight foil or plastic membrane, fully sealed to perimeter edges |

| Insulation (optional) | Mineral wool for sound/thermal buffering where needed |

| Fasteners & Anchoring | Corrosion-resistant screws and compatible wetroom fixings |

| Sealing Products | Butyl tape, sealing compound, and edge reinforcement tapes |

All products used are CE-certified and conform to TEK17 and EN 13964/EN 13501 where applicable.

Installation Tips for Wetroom Gips Walls – Sealing, Framing, and Surface Prep

- Full-Surface Sealing: Vapor barriers must be continuous behind fixtures and tiles

- Framing Choice: Moisture-treated wood or galvanized steel preferred in all wet zones

- Penetration Protection: Pipes, sockets, or niche cutouts must be fully sealed with collars or gaskets

- Tile-Ready Surface: Surface boards compatible with tile adhesive systems

- Ventilation Coordination: Ensures system dries properly and maintains air quality

- Drainage Zones: Additional backing can be added behind wall-hung toilets or plumbing units

Andronor Tip:

Always pair this system with floor-to-wall joint sealing and pre-tiled floor prep to ensure full moisture control. For high-risk walls (e.g., behind showers), we recommend dual sealing with both foil membrane and waterproof surface board.

Wetroom Gips Wall Performance Levels – Moisture, Fire & Tiling Readiness

Wetroom-rated wall systems must perform across multiple risk zones – from splash-prone areas to steam-heavy environments. Below are tested variants:

| Variant | Moisture Suitability | Fire Resistance | Tile-Ready |

| Mold-Resistant Gips Only | Moderate humidity | EI30 | Yes |

| Gips + Vapor Barrier | High humidity/wet zones | EI30–EI60 | Yes |

| Gips + Dual Membrane Sealing (full wrap) | Continuous wet exposure | EI60+ (if insulated) | Yes (with prep) |

All classifications based on manufacturer test assemblies (Gyproc, Norgips, SINTEF approvals). Documentation available on request.

Wetroom-Grade Wall Materials & Manufacturer Compliance

This system is built and installed in full compliance with:

- TEK17 Wetroom Norms

- EN 13501 fire resistance

- EN 13964 system assembly for interior structures

- NS 3510 and SINTEF Byggforsk Wet Room Guidance (for approved membranes and sealing)

Trusted material manufacturers:

- Gips Boards: Gyproc Glasroc H, Norgips Humidboard

- Membranes: Litex, Schluter, Weber WetGuard systems

- Sealants: Dana Lim wetroom sealants, butyl-based tapes

- Framing Profiles: Galvanized CW/UW 0.56–0.75 mm

Fixings: Corrosion-resistant screws